Test House Services... where our technical imagination meets reality

Where LHS Services provides the experience to meet the task.

Through our test house services we often assist our clients with specialist projects where we get the opportunity to apply our knowledge and use high accuracy test house equipment.

Through our test house services we often assist our clients with specialist projects where we get the opportunity to apply our knowledge and use high accuracy test house equipment.

In 1996 our company presented our inspection programme CLASS to the National Maintenance Professional Awards. Our presentations final slide was "if it can be dreamt of it can be done". We went on to win the award and we have the same open mind today that can bring another dimension to projects.

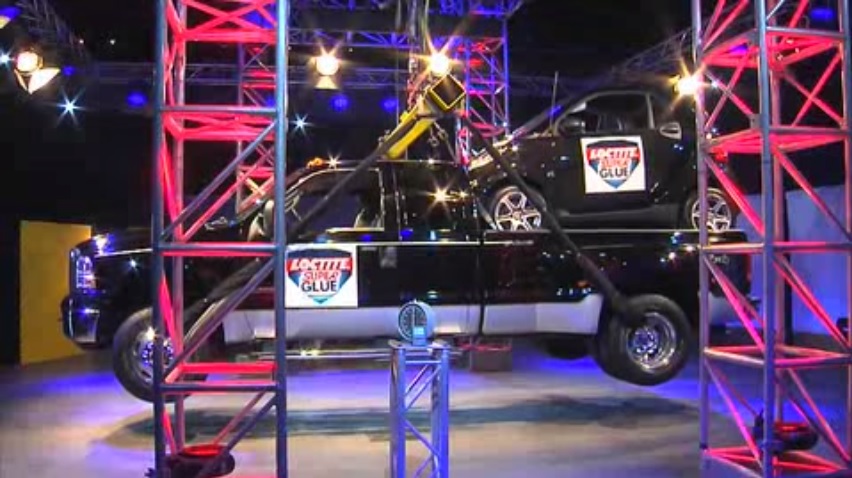

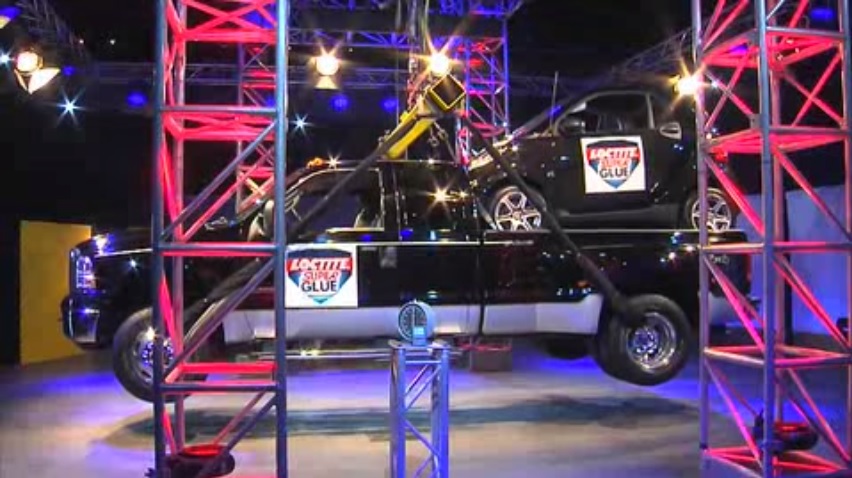

Loctite Superglue

One such example is that Loctite Superglue can now justifiably claim to be the strongest glue in the world. Just nine drops were sufficient enough to convince the jury. The Guinness World Record of the "heaviest vehicle lifted with glue" now belongs to Loctite. With a black pick-up truck giving a piggyback ride to an additional city car, Loctite Superglue secured an overall weight of exactly 5.02 tonnes - almost one tonne on top of the old record.

LHS Services assisted Loctite with this project, who went on in further attempts to beat their own record. We thoroughly enjoyed the challenge and we are proud to say we have helped to prove that Loctite truly is the best superglue in the world.

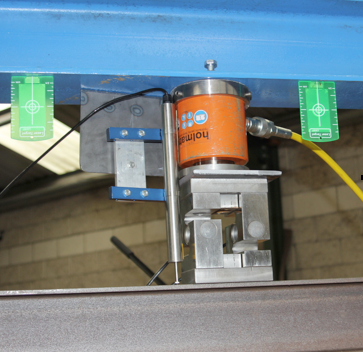

Proof of design by testing ROPS (Roll Over Protection System)

ROPS testing involves mounting a ROPS cab to a representative machine chassis specimen, and fixing the entire assembly to a rigid test bed. The test is conducted on the same test specimen in the following sequence:

- Lateral load force and energy absorption

- Vertical load force

- Longitudinal load force

- Loadings are calculated according to category and mass of machine.

LHS Services assisted our client with this project where we designed the test rig around the vehicle minimising any deflection that would affect the loadings during the data collection.

The data collection included a hydraulic force applied with displacement sensors measuring the displacement values. The loadings were, Lateral Loading of 36000 N, Vertical Loading 112000 N and Longitudinal Loading 28800 N. With the readings been taken every second we were able to graph the entire process and prove that the required standards were met in full and the vehicle passed the ROPS test.

Some of the other projects which LHS have completed -

1. Assisting our client in the design and load testing of cross arm support system for a fibre-rap programme.

Read More

2. Assisting our client in the load testing of a cross arm verification for 100 year storm, wind, snow, ice loading.

Read More

3. Designing and building a support system for 120000 kg dam beams, the project included multiple proof loading of the dam beams.

Read More

4. Assisting our client in the proof of concept for a cable repair joint of inter connector cable between Northern Ireland and England which was under water at a depth of 26.6 metre below sea level.

Read More

5. Specialised Consultancy on Lifting Equipment for Hydro Stations

Read More

Safety inspection, certification and calibration of materials handling and safety equipment is Lifting and Handling Services speciality. Contact us for technical and legal advice on +35345 868342 (email: info@liftingandhandling.ie) or visit our download section.

Through our test house services we often assist our clients with specialist projects where we get the opportunity to apply our knowledge and use high accuracy test house equipment.

Through our test house services we often assist our clients with specialist projects where we get the opportunity to apply our knowledge and use high accuracy test house equipment.